MIM- Aluminium alloy

Materialintroduction: The MIM process is used to producehigh-strength aluminum alloy products, the mechanical properties of thematerial are close to the plate, and it does not contain Sn and otherstrength-reducing elements. It is advantageous for the processing of small andcomplex products of aluminum alloy.

Elementcomposition:

|

Si |

Cu |

Mg |

Sn |

Al |

|

0.4~0.8 |

0.1~0.4 |

0.5~1.5 |

- |

Bal. |

Physicalproperties:

|

Properties |

Unit |

After heat treatment |

|

Density ρ |

g/cm3 |

>2.65 |

|

Hardness |

Hv |

100 |

|

Tensile strength Rm |

MPa |

200 |

|

Yield strength Rp0.2 |

MPa |

300 |

|

Elongation A10 |

% |

5 |

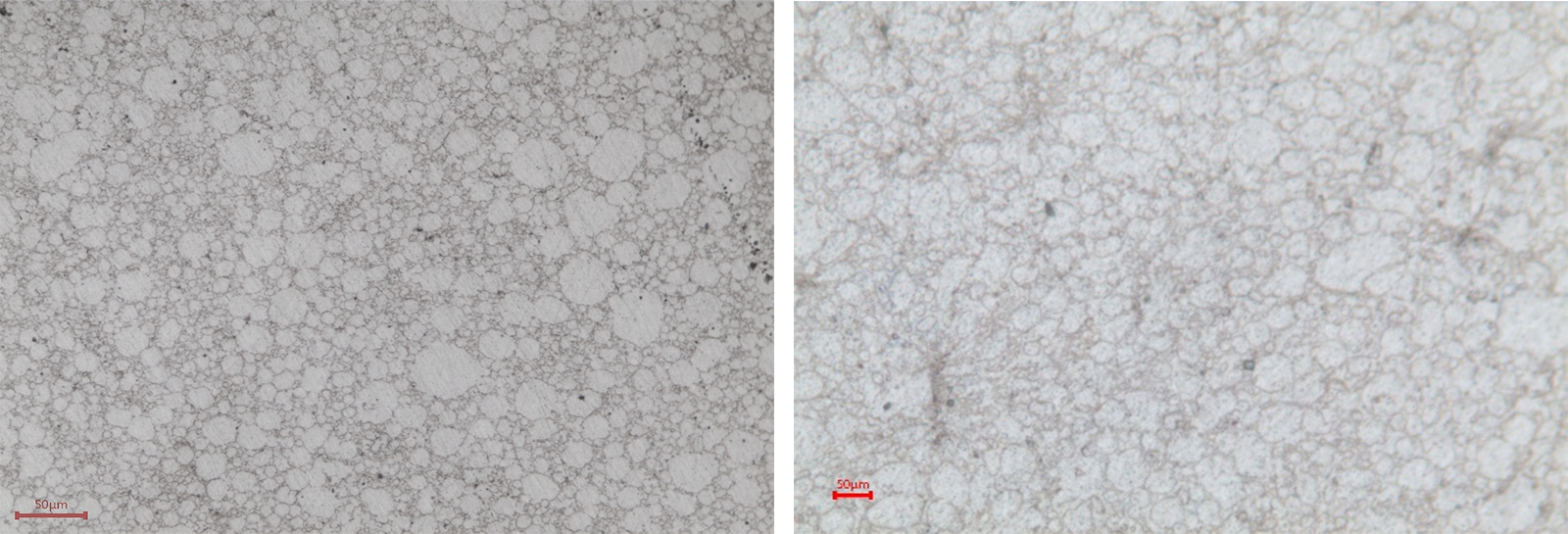

Metallography(×200)

Comparisonof the properties of different aluminum alloys

|

Material |

Tensile strength Rm Mpa |

Yield strength Rp0.2 Mpa |

Elongation |

Density g/cm3 |

Hardness |

|

Aluminum sheet (6061) (Thickness=1.5~3) |

290 |

240 |

7 |

2.75 |

|

|

die-cast aluminum (ADC12) |

230 |

- |

1 |

2.70 |

80 HBW |

|

MIM- Aluminum |

300 |

210 |

6.0 |

>2.65 |

100 Hv |

Comparisonof processing of complex shape aluminum alloy

|

Item |

Material cost |

Mass production cost |

Efficiency |

Accuracy |

Anodizing |

|

CNC |

Low |

High |

Low |

High |

Able |

|

Die casting |

Low |

Low |

High |

High |

Unable |

|

3D Printing(SLM) |

High |

High |

Low |

Low |

Able |

|

MIM-Al |

Low |

Low |

High |

High |

Able |