High temperature alloys

Material introduction: Such materials at high temperatures in the mechanical properties of the reduction of small, can be in the 600 ℃ above the high temperature long-term work, and has a high high-temperature strength, good oxidation and corrosion resistance, good fatigue properties, fracture toughness and other comprehensive performance. Applied to the use of parts and components in a high-temperature environment.

Element composition:

|

Model |

C |

Cr |

Ni |

Co |

W |

Nb |

Mo |

Fe |

|

1.4957 |

0.4~0.45 |

20±2 |

21±2 |

18.5~21 |

2~3 |

1±0.25 |

3.5±1 |

Bal. |

|

Model |

C |

Cr |

Al |

Mo |

Ti |

Si |

Mn |

Nb |

Ni |

|

Inco713C |

0.08~0.25 |

13±1 |

6±0.5 |

3.8~5.2 |

0.5~1 |

≤0.25 |

≤0.25 |

1.8~2.9 |

Bal. |

|

Model |

C |

Cr |

Ni |

Si |

Mn |

Nb |

Mo |

Fe |

|

HK30 |

0.25~0.5 |

25±1 |

19~22 |

0.75~1.3 |

≤1.5 |

1.2~1.5 |

≤0.5 |

Bal. |

|

Model |

C |

Cr |

Ni |

Si |

Mn |

W |

Mo |

Fe |

|

1.4091 |

1~1.2 |

35±1 |

15±1 |

≤1 |

≤1 |

0.4~0.85 |

3±1 |

Bal. |

Physical properties:

|

Properties |

Unit |

1.4957 |

Inco713C |

HK30 |

1.4091 |

|

Density ρ |

g/cm3 |

>7.80 |

>7.80 |

>7.55 |

>7.40 |

|

Hardness |

Hv |

170 |

320 |

190 |

310 |

|

Tensile strength Rm |

MPa |

650 |

1370 |

580 |

800 |

|

Yield strength Rp0.2 |

MPa |

250 |

900 |

290 |

500 |

|

Elongation A10 |

% |

30 |

16 |

20 |

2 |

800℃ high temperature mechanical properties

|

Model |

Testing temperature ℃ |

Tensile strength Rm MPa |

Yield strength Rp0.2 MPa |

Elongation A10 % |

|

1.4957 |

850 |

270 |

165 |

15 |

|

Inco713C |

600 |

1100 |

1000 |

4.5 |

|

1050 |

170 |

110 |

9 |

|

|

HK30 |

600 |

560 |

280 |

15 |

|

800 |

300 |

200 |

25 |

|

|

850 |

290 |

200 |

30 |

|

|

1.4091 |

800 |

400 |

230 |

9 |

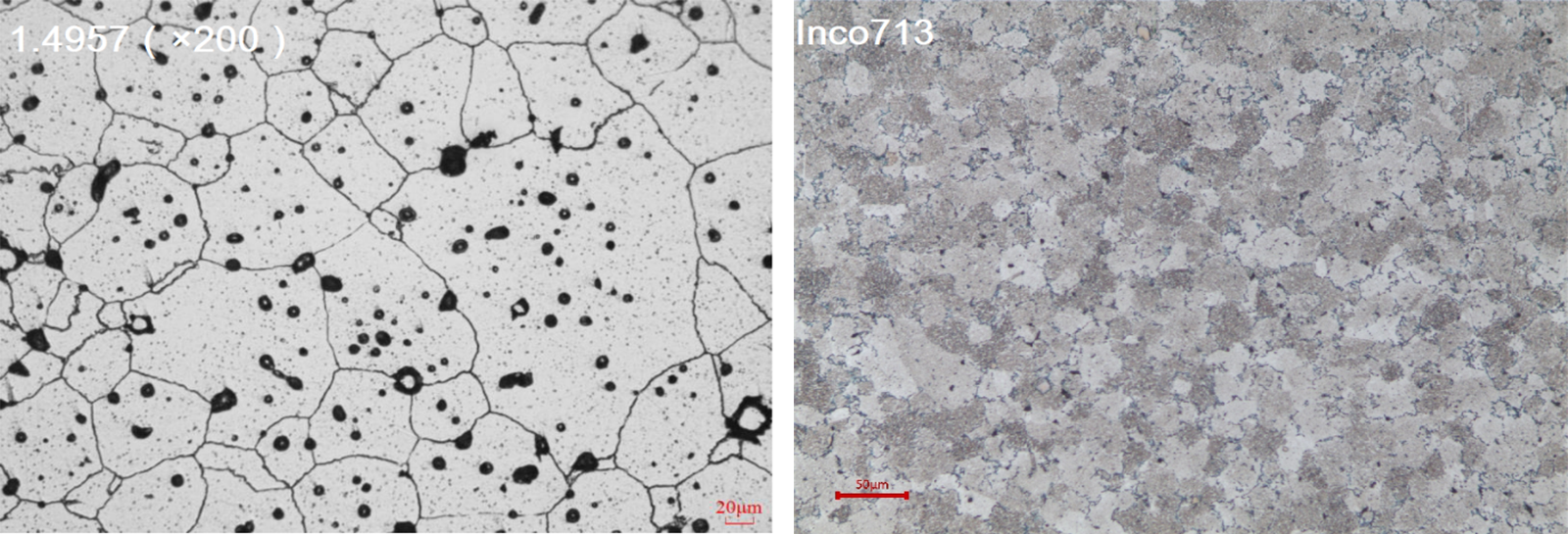

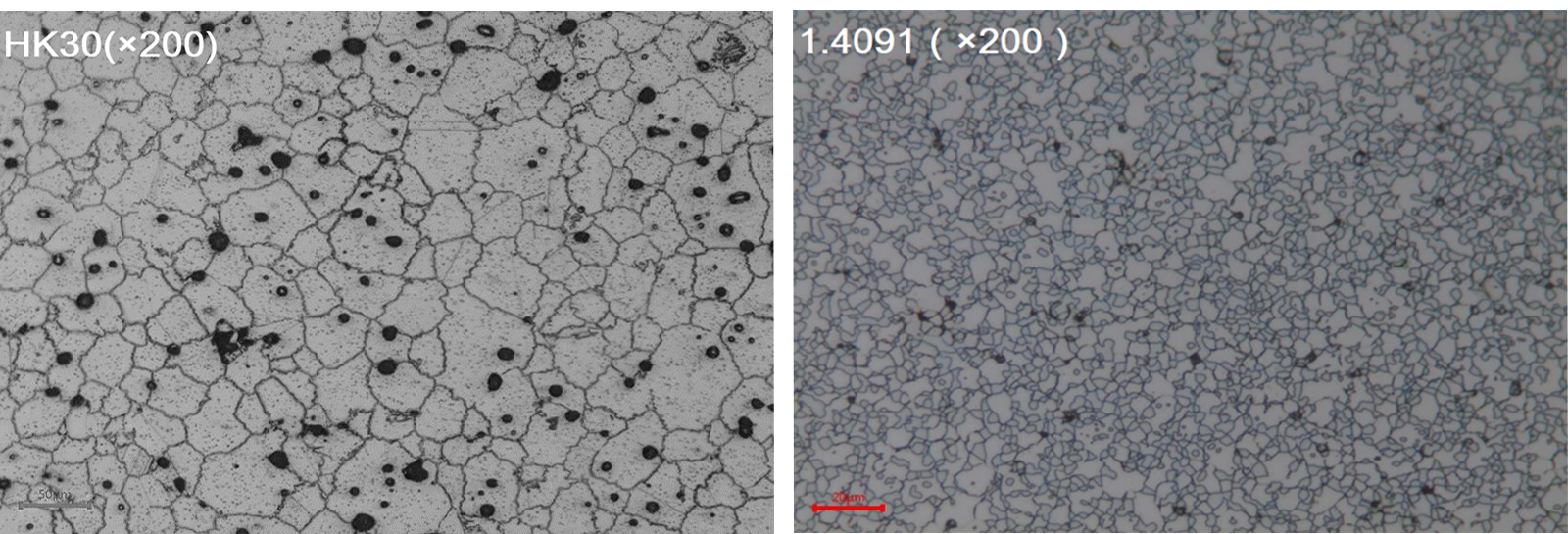

Metallography (×500)